Best Sellers

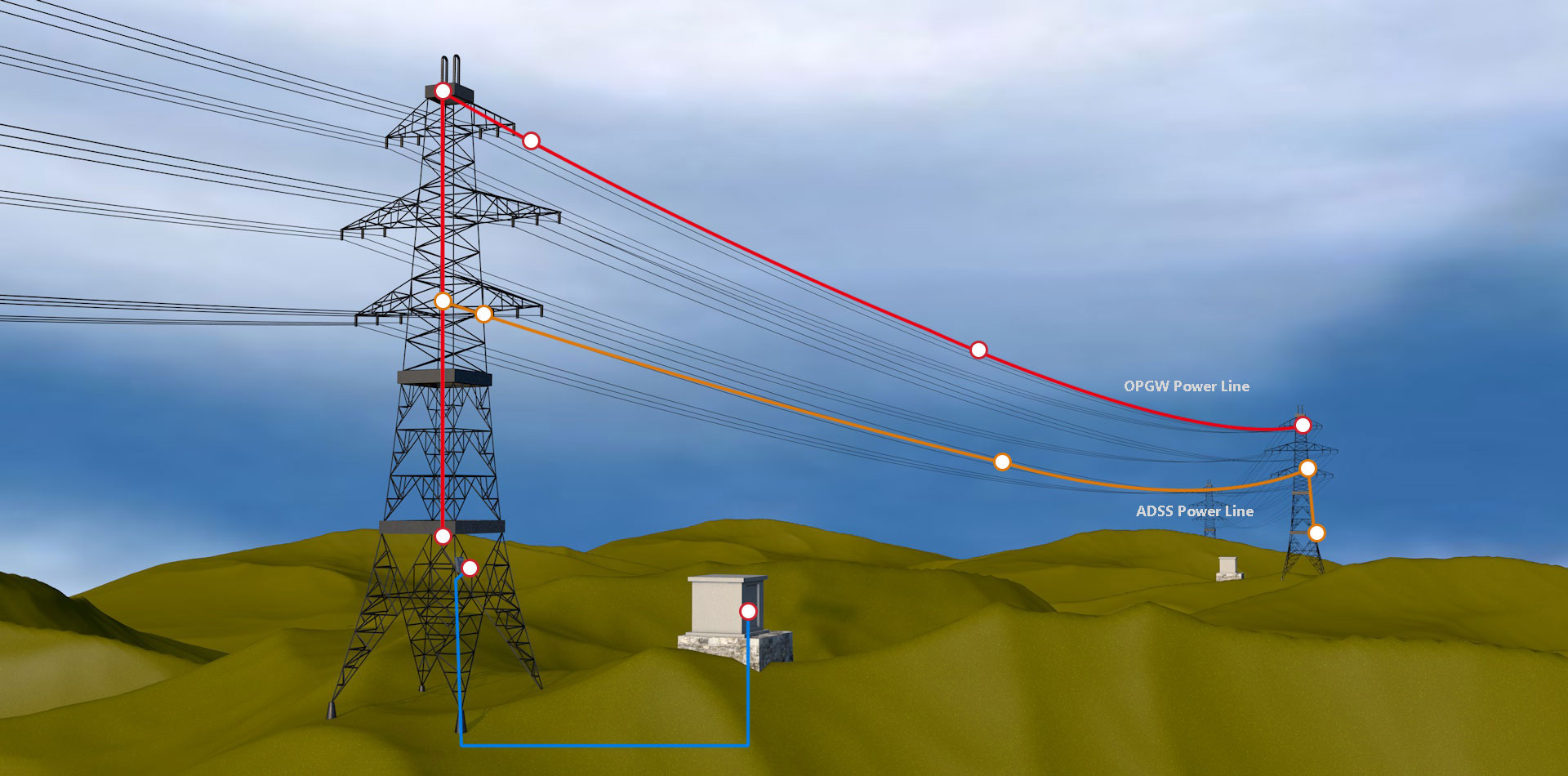

ADSS/OPGW/FTTH Drop Fiber Cable Products

-

ADSS Fiber Optic Cable

Single & Doube Jackets ADSS Cable; Excellent AT performance. The maximum inductive at the operating point Of AT jacket can reach 25kV

-

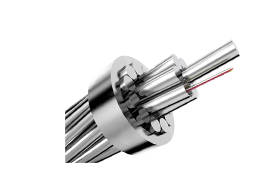

OPGW Fiber Optic Cable

KSD provide years of experience and excellent solutions for your hardware needs in OPGW (Optical Ground Wire) cables.

-

FTTH Drop Cable

GJXFH/ GJYXFCH/ GJYXFCH/ STEEL STEEL STRAND GJYXFFCH/ GJXFH/ GJYXFCH(V) STEEL/ GYXTC8KH

-

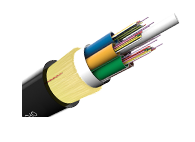

Outdoor Fiber Optic Cable

Aerial/ Direct-buried/ Duct Fiber Optic Cables;ADSS / OPGW/ GYTA / GYFTY GYTA53 / GYXTW /FTTH / GYTS

-

Indoor Fiber Optic Cable

Single mode indoor fiber optic cable OM2 multi-mode indoor fiber optic cable OM3 multi-mode indoor fiber optic cable

-

Air Blown Fiber Optic Cable

-Small diameter -Long blowing distance -Excellent Structure