Cable Cross -Section:

Fiber color code:

Fiber color in each tube starts from No. 1 Blue.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Blue | Orange | Green | Brown | Gray | White | Red | Black | Yellow | Violet | Pink | Aqua |

Color codes for loose tube:

| 1 |

| Nature |

Cable structure and parameter

| SN | Item | Unit | Value |

| 1 | No. of fibers | count | 2/4/6/8/12 |

| 2 | FRP diameter(nominal) | mm | 2 |

| 3 | Cable diameter(±5%) | mm | 6.6 |

| 4 | Cable weight(±10%) | kg/km | 42 |

| 5 | Tension | N | 1600/800 |

| 6 | Crush | N/100mm | 1000/300 |

Characteristic of Optical Cable:

- Min. bending radius for installation

- Static: 15 x cable diameter

- Dynamic: 30 x cable diameter

Application temperature range:

Operation: – 20℃ ~ +65℃

Installation: -10℃ ~ +60℃

Storage/transportation: – 20℃ ~ +65℃

Main Mechanical & Environmental Performance Test:

| Item | Test Method | Acceptance Condition |

| Tensile Strength | - Load: Short term tension | - Fiber strain £ 0.33% |

| IEC 60794-1-2-E1 | - Length of cable: about 50m | - No fiber break and no sheath damage. |

| - Load time: 1min | ||

| Crush Test | - Load: Short term crush | - Loss change £ 0.1dB@1550nm |

| IEC 60794-1-2-E3 | - Load time: 1min | - No fiber break and no sheath damage. |

| Temperature Cycling | - Temperature: -20oC~+60oC | - Loss change £ 0.1dB/km@1550nm |

| IEC 60794-1-2-F1 | - Time of each step: 12h | - No fiber break and no sheath damage. |

| - Number of cycles: 2 |

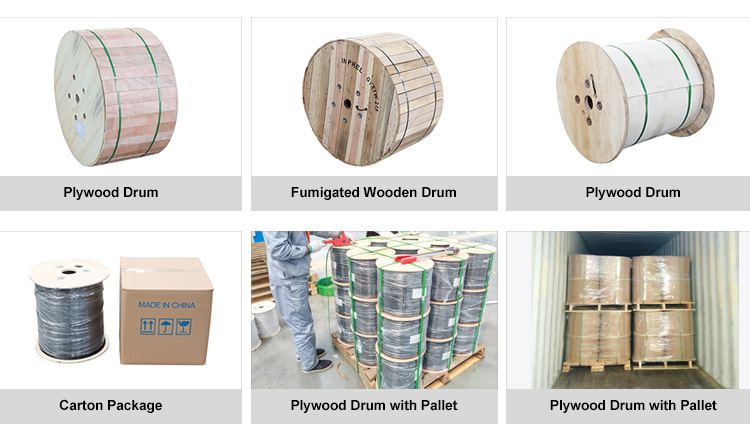

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping: