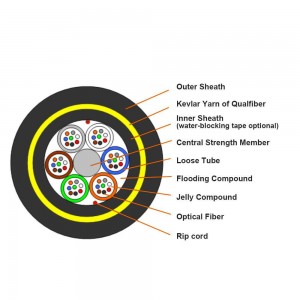

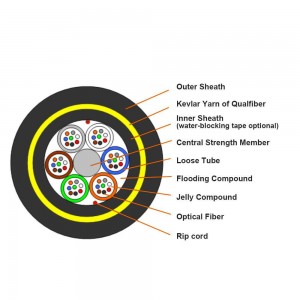

Cable Cross -Section:

Span: 500-1500m

Application: Self-support Aerial installation

Main Features:

Long Span Installation & Use

Tailored designs span distances up to 2,500’ (760 m) without interrupting power

Higher count designs utilize 24 fiber per tube to reduce environmental load

Matching pole attachment hardware (dead-ends, suspension clamps)

Standards: IEEE 1222, IEC 60794-4-20, ANSI/ICEA S-87-640, TELCORDIA GR-20, IEC 60793-1-22, IEC 60794-1-2, IEC 60794

Double Layer Aerial ADSS CableTechnical Parameter:

| Parameters | Specification | |

| Optical Characteristics | ||

| Fiber Type | G652.D | |

| Mode Field Diameter (um) | 1310nm | 9.1 ± 0.5 |

| 1550nm | 10.3 ± 0.7 | |

| Attenuation Coefficient (dB/km) | 1310nm | ≤ 0.35 |

| 1550nm | ≤ 0.21 | |

| Attenuation Non-uniformity (dB) | ≤ 0.05 | |

| Zero Dispersion Wavelength ( λ0) (nm) | 1300 ~ 1324 | |

| Max Zero Dispersion Slope (S0max) (ps/(nm2·km)) | ≤ 0.093 | |

| Polarization Mode Dispersion Coefficient (PMDQ) (ps/km1/2) | ≤ 0.2 | |

| Cut-off Wavelength (λcc) (nm) | ≤ 1260 | |

| Dispersion Coefficient (ps/ (nm·km)) | 1288~1339nm | ≤ 3.5 |

| 1550nm | ≤ 18 | |

| Effective Group Index of Refraction (Neff) | 1310nm | 1.466 |

| 1550nm | 1.467 | |

| Geometric characteristic | ||

| Cladding Diameter (um) | 125.0 ± 1.0 | |

| Cladding Non-circularity (%) | ≤ 1.0 | |

| Coating Diameter (um) | 245.0 ± 10.0 | |

| Coating-cladding Concentricity Error (um) | ≤ 12.0 | |

| Coating Non-circularity (%) | ≤ 6.0 | |

| Core-cladding Concentricity Error (um) | ≤ 0.8 | |

| Mechanical characteristic | ||

| Curling (m) | ≥ 4 | |

| Proof Stress (GPa) | ≥ 0.69 | |

| Coating Strip Force (N) | Average Value | 1.0 5.0 |

| Peak Value | 1.3 ~ 8.9 | |

| Macro Bending Loss (dB) | Ф60mm, 100 Circles, @ 1550nm | ≤ 0.05 |

| Ф32mm, 1 Circle, @ 1550nm | ≤ 0.05 | |

Specifications:

| Parameters | Specification | ||||||

| Fiber Count | 2 | 6 | 12 | 24 | 60 | 144 | |

| Loose Tube | Material | PBT | |||||

| Fibers per Tube | 2 | 4 | 4 | 4 | 12 | 12 | |

| Numbers | 1 | 2 | 3 | 6 | 5 | 12 | |

| Filler Rod | Numbers | 5 | 4 | 3 | 0 | 1 | 0 |

| Central Strength Member | Material | FRP | FRP coated PE | ||||

| Water Blocking Material | Water blocking yarn | ||||||

| Additional Strength Member | Aramid yarns | ||||||

| Inner Jacket | Material | Black PE (Polythene) | |||||

| Thickness | Nominal: 0.8 mm | ||||||

| Outer Jacket | Material | Black PE (Polythene) or AT | |||||

| Thickness | Nominal: 1.7 mm | ||||||

| Cable Diameter (mm) | 11.4 | 11.4 | 11.4 | 11.4 | 12.3 | 17.8 | |

| Cable Weight (kg/km) | 94 ~ 101 | 94 ~ 101 | 94 ~ 101 | 94 ~ 101 | 119 ~ 127 | 241 ~ 252 | |

| Rated Tension Stress (RTS) (KN) | 5.25 | 5.25 | 5.25 | 5.25 | 7.25 | 14.5 | |

| Maximum Working Tension (40%RTS) (KN) | 2.1 | 2.1 | 2.1 | 2.1 | 2.9 | 5.8 | |

| Everyday Stress (15-25%RTS) (KN) | 0.78 ~ 1.31 | 0.78 ~ 1.31 | 0.78 ~ 1.31 | 0.78 ~ 1.31 | 1.08 ~ 1.81 | 2.17 ~ 3.62 | |

| Allowable Maximum Span (m) | 100 | ||||||

| Crush Resistance (N/100mm) | Short time | 2200 | |||||

| Suiting Meteorological Condition | Max wind speed: 25m/s Max icing: 0mm |

||||||

| Bending Radius (mm) | Installation | 20D | |||||

| Operation | 10D | ||||||

| Attenuation (After Cable) (dB/km) | SM Fiber @1310nm | ≤ 0.36 | |||||

| SM Fiber @1550nm | ≤ 0.22 | ||||||

| Temperature Range | Operation (℃) | -40 ~ +70 | |||||

| Installation (℃) | -10 ~ +50 | ||||||

| Storage & Shipping (℃) | -40 ~ +60 | ||||||

Note:

1. Only a part of Double Layer Aerial ADSS Cable are listed in the table. More can be produce as required .

2. Cables can be supplied with a range of single mode or multimode fibers.

3. Cables can be supplied with dry core or semi dry core

4. Specially designed Cable structure is available on request.

We are Aerial ADSS Cable manufacturer,Factory Price Supply Aerial ADSS Cable and adss cable hardware.

Want to know Aerial ADSS Cable price,please send email to sales@ksdfibercable.com

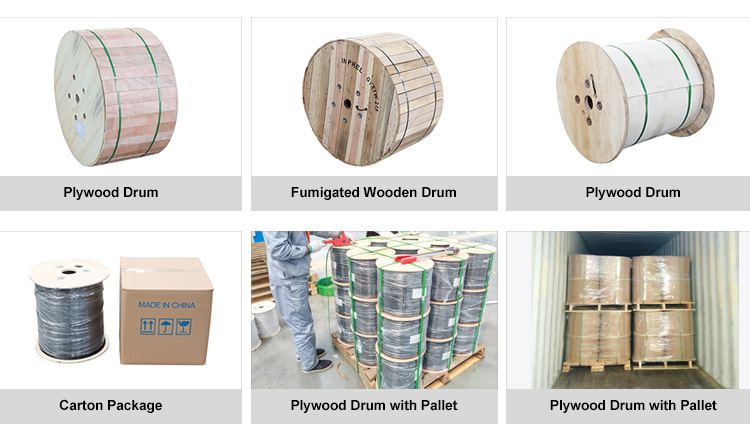

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping:

-

Long Span ADSS Fiber Optic Cable 200m-1000m

-

Mini Span ADSS Fiber Optic Cable 50-150m

-

24 Core Single Jacket Aerial ADSS Fiber Optical...

-

Aerial Non-metal Double Jacket G652d ADSS Fiber...

-

ASU(Mini ADSS) Aerial Self-Supported ASU Fiber ...

-

ASU80 1-12 Core Outdoor Cable, ADSS, G652D

-

Cable de Fibra Optica ADSS 6/12/24/48/96/144/28...