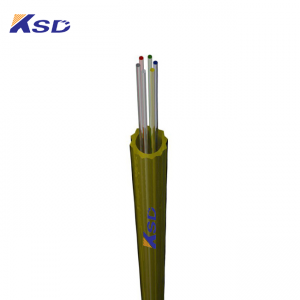

Structure Design

Application

Aerial/Duct/Outdoor

Characteristic

1. Excellent mechanical and temperature performance guaranteed by the accurate excess fiber lent.

2. Critical protection to fibers, based on the excellent hydrolysis resistance.

3. Excellent crush resistance and flexibility.

4. PSP enhances the cable crush-resistance, impact-resistance and moisture-proof.

5. Two parallel steel wires ensure tensile strength. 6. Excellent ultraviolet prevention with PE sheath,small diameter, light weight and installation friendliness.

Temperature Rage

Operating :-40℃ to +70℃ Storage :-40℃ to +70℃

Standards

Comply with standard YD/T 769-2010

Technical Characteristics

1)The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

2)The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties Multiple water blocking material filling provides dual water blocking function

B1.3(G652D) single mode fiber

| Optics Specifications | |||

| Attenuation(dB/km) | @1310nm | ≤0.36db/km | |

| @1383nm (after hydrogen aging) | ≤0.32db/km | ||

| @1550nm | ≤0.22db/km | ||

| @1625nm | ≤0.24db/km | ||

| Dispersion | @1285nm~1340nm | -3.0~3.0ps/(nm*km) | |

| @1550nm | ≤18ps/(nm*km) | ||

| @1625nm | ≤22ps/(nm*km) | ||

| Zero-Dispersion wavelength | 1300~1324nm | ||

| Zero-Dispersion slope | ≤0.092ps/(nm2*km) | ||

| Mode field diameter @ 1310nm | 9.2±0.4μm | ||

| Mode field diameter @ 1550nm | 10.4±0.8μm | ||

| PMD | Max. value for fiber on the reel | 0.2ps/km 1/2 | |

| Max. Designed value for link | 0.08ps/km 1/2 | ||

| Cable cutoff wavelength,λ cc | ≤1260nm | ||

| Effective group index(Neff)@1310nm | 1.4675 | ||

| Effective group index(Neff)@1550nm | 1.4680 | ||

| Macro-bend loss(Φ60mm,100 turns)@1550nm | ≤0.05db | ||

| Back scatter characteristic(@1310nm&1550nm) | |||

| Point discontinuity | ≤0.05db | ||

| Attenuation uniformity | ≤0.05db/km | ||

| Attenuation coefficient difference for bi-directional measurement | ≤0.05db/km | ||

| Geometrical characteristics | |||

| Cladding diameter | 125±1μm | ||

| Cladding non-circularity | ≤1% | ||

| Core/cladding concentricity error | ≤0.4μm | ||

| Fiber diameter with coating(uncolored) | 245±5μm | ||

| Cladding/coating concentricity error | ≤12.0μm | ||

| Curl | ≥4m | ||

| Mechanical characteristic | |||

| Proof test | 0.69GPa | ||

| Coating strip force(typical value) | 1.4N | ||

| Dynamic stress corrosion susceptibility parameter(typical value) | ≥20 | ||

| Environmental characteristics(@1310nm&1550nm) | |||

| Temperature induced attenuation(-60~+85℃) | ≤0.5dB/km | ||

| Dry heat induced attenuation(85±2℃,30days) | ≤0.5dB/km | ||

| Water immersion induced attenuation(23±2℃,30days) | ≤0.5dB/km | ||

| Damp heat induced attenuation(85±2℃,RH85%,30days) | ≤0.5dB/km | ||

GYXTW Fiber Cable Technical Parameter

| Fiber Number | 24 | 48 |

| Fiber No. per tube | 4 | 4 |

| Number of Loose tube | 6 | 12 |

| Loose tube diameter | 1.8mm | |

| Loose tube material | PBT polybutylece terephthalate | |

| Gel filled in loose tube | Yes | |

| Messenger wire | 2X1.0mm | |

| Cable OD | 10mm | |

| Operation temperature range | -40 deg C to + 70 deg C | |

| Installation temperature range | -20 ℃ to + 60 ℃ | |

| Transport and storage temperature range | -40 ℃ to + 70 ℃ | |

| Tensile force(N) | Short term 1500N Long term 1000N | |

| Minimal installation bending radius | 20 x OD | |

| Minimal operation bending radius | 10 x OD | |

Noted:

1,Only a part of Aerial/Duct/Direct Buried/Underground/Armoured cables are listed in the table. Cables with other specifications can be inquired.

2,Cables can be supplied with a range of single mode or multimode fibers.

3,Specially designed Cable structure is available on request.