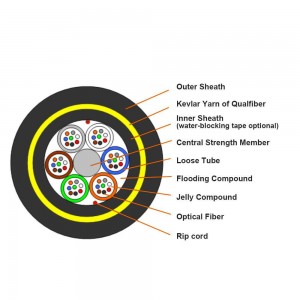

Cable Cross -Section:

Applications:

The design of the ADSS optical cable fully considers the actual situation of the power line, and is suitable for different levels of high-voltage transmission lines. For 10 kV and 35 kV power lines, polyethylene (PE) sheaths can be used; for 110 kV and 220 kV power lines, the distribution point of the optical cable must be determined by calculating the electric field strength distribution and an outer track (AT) outer sheath. At the same time, the amount of aramid fiber and the perfect twisting process are carefully designed to meet the application requirements of different spans.

Product Standards:

The ADSS optical cable complies with the IEEE 1222 technical standard and complies with the IEC 60794-1 standard.

Features:

• Uninterruptible power erection

• Adopt AT sheath, excellent resistance to tracking

• Light weight and small cable diameter reduce the impact of ice, wind and load on towers and supports

• Large span, maximum span exceeds 1000 meters

• Has excellent tensile properties and temperature characteristics

• Life expectancy is greater than 30 years

Technical Parameters:

|

Reference outer diameter (Mm) |

reference weight (Kg / km) |

Recommended daily maximum working tension (KN) |

Maximum allowable working tension (KN) |

Breaking strength (KN) |

Tensile element cross-sectional area (mm2) |

Elastic Modulus (kN / mm2) |

Thermal expansion coefficient × 10-6 / K |

Suitable range (m) Corresponding weather conditions (m) |

||||

|

PE outer sheath |

AT outer guard |

A |

B |

C |

D |

|||||||

|

11.8 |

117 |

124 |

1.5 |

4 |

10 |

4.6 |

7.6 |

1.8 |

160 |

100 |

140 |

100 |

|

12.0 |

121 |

129 |

2.25 |

6 |

15 |

7.6 |

8.3 |

1.5 |

230 |

150 |

200 |

150 |

|

12.3 |

126 |

134 |

3.0 |

8 |

20 |

10.35 |

9.45 |

1.3 |

300 |

200 |

290 |

200 |

|

12.6 |

133 |

141 |

3.6 |

10 |

24 |

13.8 |

10.8 |

1.2 |

370 |

250 |

350 |

250 |

|

12.8 |

138 |

145 |

4.5 |

12 |

30 |

14.3 |

11.8 |

1.0 |

420 |

280 |

400 |

280 |

|

13.1 |

145 |

153 |

5.4 |

15 |

36 |

18.4 |

13.6 |

0.9 |

480 |

320 |

460 |

320 |

|

13.5 |

155 |

163 |

6.75 |

18 |

45 |

22.0 |

16.4 |

0.6 |

570 |

380 |

550 |

380 |

|

13.8 |

163 |

171 |

7.95 |

22 |

53 |

26.4 |

18.0 |

0.3 |

670 |

460 |

650 |

460 |

|

14.4 |

177 |

186 |

9.0 |

26 |

60 |

32.2 |

19.1 |

0.1 |

750 |

530 |

750 |

510 |

|

14.6 |

182 |

191 |

10.5 |

28 |

70 |

33.0 |

19.6 |

0.1 |

800 |

560 |

800 |

560 |

|

14.8 |

195 |

204 |

12.75 |

34 |

85 |

40.0 |

20.1 |

0.1 |

880 |

650 |

880 |

650 |

Storage and use temperature: -40 ℃ to + 70 ℃. A

Optical characteristics:

|

Fiber type |

attenuation (+ 20 ℃) |

bandwidth |

Numerical aperture |

Optical fiber cut-off wavelength |

||||

|

@850nm |

@1300nm |

@1310nm |

@1550nm |

@850nm |

@1300nm |

|||

|

G.652 |

— |

— |

≤0.36dB/km |

≤0.22dB/km |

— |

— |

— |

≤1260nm |

|

G.655 |

— |

— |

≤0.40dB/km |

≤0.23dB/km |

— |

— |

— |

≤1450nm |

|

50/125µm |

≤3.3dB/km |

≤1.2dB/km |

— |

— |

≥500MHz·km |

≥500MHz·km |

0.200±0.015 NA |

— |

|

62.5/125µm |

≤3.5dB/km |

≤1.2dB/km |

— |

— |

≥200MHz·km |

≥500MHz·km |

0.275±0.015 NA |

— |

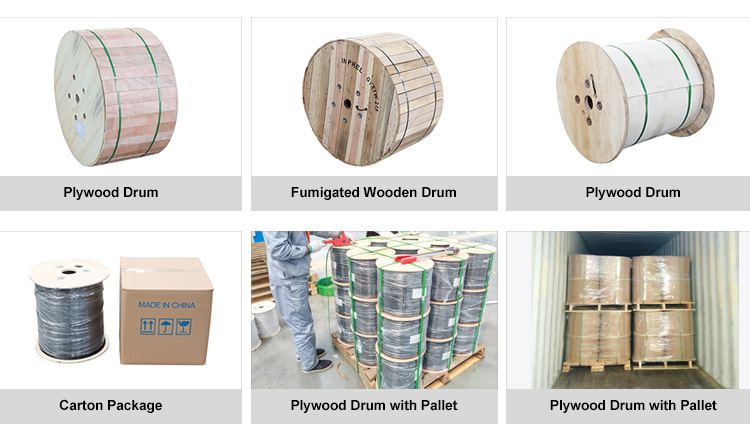

Packing and Marking:

- Each single length of cable shall be reeled on Fumigated Wooden Drum

- Covered by plastic buffer sheet

- Sealed by strong wooden battens

- At least 1 m of inside end of cable will be reserved for testing.

- Drum length: Standard drum length is 3,000m±2%; as required

- 5.2 Drum Marking(can according to the requirement in the technical specification) Manufacturer name;

- Manufacturing year and month Roll—direction arrow;

- Drum length; Gross/net weight;

Packaging and Shipping:

-

Long Span ADSS Fiber Optic Cable 200m-1000m

-

Mini Span ADSS Fiber Optic Cable 50-150m

-

48 Core Aerial Non Metallic ADSS Cable With HDP...

-

12 Core ADSS Optical Cable Self Supporting 100 ...

-

ADSS Double Suspension Clamp

-

ADSS Optical Cable Joint Box/Splice Closure/Joi...

-

ADSS Series Tension Clamp

-

ADSS/OPGW Down Lead Clamp